6 Ways to Maximize Efficiency for E-commerce Warehousing

The promise of one- and same-day shipping has put pressure on traditional warehouse processes for managing inventory to keep pace with consumer demand for rapid order fulfillment. In fact, the shift from traditional brick-and-mortar to e-commerce operations is increasing as a result of the coronavirus pandemic.

The pressure on warehouse operators is underlined when you consider that online order fulfillment requires about three times more logistics space than a traditional warehouse. That’s because 100% of inventory is stored within a warehouse to allow for greater product variety, deeper inventory levels, space-intensive parcel shipping operations and additional value-add activities such as processing returns.

To remain competitive in today’s world of e-commerce, warehouse optimization is essential. Below we analyze six strategies you can implement to optimize e-commerce warehouse layouts for greater efficiency.

Analyzing your current picking and packing strategy to align with frequently sold products can help you identify how to improve your warehouse layout.

Analyzing your current picking and packing strategy to align with frequently sold products can help you identify how to improve your warehouse layout.

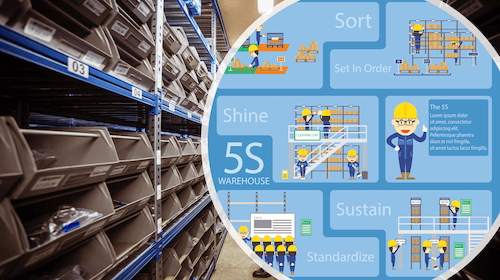

1. Adopt lean warehouse operations practices

Many warehouses are particularly well suited to adopt lean warehouse strategies. Proper labeling plays a foundational role in helping warehouses adopt lean practices. Adding warehouse labels to bins, racking and shelves helps eliminate the inefficiencies and organizational waste.

With today’s state-of-the-art digital inkjet presses, adding warehouse labels to bins, racking and shelves is a cost-effective way to eliminate inefficiencies. There are a wide variety of standard and custom options available in multiple colors and graphics, with either linear or 2D barcoding that will support your e-commerce inventory management software and scanning devices.

2. Refine picking and packing layouts to support product velocity

Modern warehouses are being customized to handle smaller orders with more frequent shipping. The customization is changing the way workers pick orders. Analyzing your current picking and packing strategy to align with frequently sold products can help you identify how to improve your warehouse layout. If you decide to switch to a different strategy, it may require that you reorganize your warehouse.

This was the case for one ID Label client, a 3PL whose client is a-well known specialty food manufacturer. They opted to completely reconfigure the racking at one of their larger facilities to move their client’s product more quickly out the door. After reconsidering the layout of their warehouse, the organization relied on ID Label for the manufacture and installation of new rack labels and signage.

3. Make use of vertical space

As mentioned, e-commerce fulfillment centers can require up to three times the space of a traditional warehouse. One way they’re expanding is up.

With the demand for increased volume, warehouses are expanding and being built with higher clear heights. Where 20-foot clear heights were once common, new warehouses are reaching 40 feet.

In these facilities, it’s important to leverage long-range scanning tools to maximize efficiency. This includes barcode labels and signs manufactured with retroreflective materials and mobile technology that supports long-range scanning.

Using vertical space in your facilities will expand e-commerce inventory capacity to meet demands for velocity, while improving layout, product access, safety and efficiency.

4. Consider adding smaller distribution centers near urban areas

As consumers look to get the items they order delivered within a single day, the distance between consumers and the product is continuing to shrink. According to an article in Supply Chain Dive, companies are beginning to rely on smaller satellite distribution centers that are closer to large cites. This helps meet the demand for quicker deliveries, which is especially critical for food and other products with a short shelf life. These facilities typically range in size between 150,000 and 200,000 square feet.

5. Invest in warehouse management software

Knowing exactly where your inventory is, how much you have and how quickly it is moving is the key to optimizing for efficiency. A warehouse management system (WMS) is a vital tool to accomplish this, especially when teamed with barcode labeling solutions, robust warehouse signage and mobile scanners to fully automate your order fulfillment and inventory management processes.

6. Take advantage of new barcode labeling solutions

As e-commerce continues to flourish, there’s a growing need for flexibility in labeling rack storage locations. Due to changes in product demand, higher return volumes or seasonal requirements, warehouse operators need flexibility to relabel pallet locations with more frequency.

There are two ID Label warehouse labeling products that are designed with this need in mind:

- Clean Release™ – a breakthrough warehouse label with an advanced adhesive, making it easy to remove and reposition rack labels to accommodate inventory location modifications.

- Beam Renew™ – a custom-engineered cover-up solution that apples directly over old or damaged warehouse labels without the time and expense of cleaning, scraping or painting.

The ID Label Advantage

ID Label designs and manufactures custom labeling solutions for e-commerce warehousing. Our materials have been tested and used in operations around the globe.

We also provide warehouse signage and turnkey nationwide installation services to provide a complete solution to our many clients who rely on us for all their warehousing needs.

Interested in learning more? Contact us today.