How Long-Range Warehouse Labels Boost Operational Efficiency

Larger Facilities Have Unique Labeling and Signage Needs

The number of warehouse projects being developed is growing, and so is the average size. From 2007 through 2018, the number of warehouse projects of one million square feet or more increased from 23 to 48, more than doubling. The construction of these larger facilities, driven largely by the boom in e-commerce, has resulted in increased use of bulk storage and high-capacity racking to accommodate the larger volume being stored.

“High bay racking in newer facilities has increased due to facilities storing more units and SKUs,” said Ken LeBlanc, a senior business development manager at ID Label. “As more facilities incorporate taller reserve racking systems, the need for new systems and processing has increased, including the need for long-range scanning solutions.”

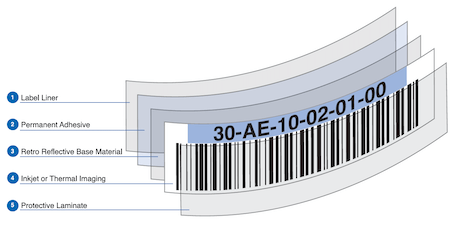

Retroreflective materials enable optimal scan accuracy from long distances—typically 50 feet or more. This is due to the intensity of the light reflecting off the barcode as it is returned to the mobile scanning device.

Rack labels can be manufactured using retroreflective graphics for long-range scanning. This is desirable when person-down lift trucks are being used and totem labels are not installed to identify/scan upper rack levels.

Rack labels can be manufactured using retroreflective graphics for long-range scanning. This is desirable when person-down lift trucks are being used and totem labels are not installed to identify/scan upper rack levels.

As a custom manufacturer, ID Label is able to construct its rack labels and signs with retroreflective materials to support a warehouse operator’s long-range scanning requirements.

ID Label’s Long-Range Scanning Solutions

As a custom manufacturer, ID Label is able to construct its rack labels and signs with retroreflective materials to support a warehouse operator’s long-range scanning requirements. Understanding the mobile technology and inventory management software being used is an important part of up-front discussions.

“For example, we worked with a large steel manufacturer to help design and implement labels to scan pieces of steel being transported by cranes,” said LeBlanc. ID Label visited the site to understand the company’s specific needs, ultimately designing a label that could be scanned from a distance of up to 70 feet.

“We had another instance installing signs for a client’s rail bays that were able to be scanned from 80 feet,” he said. “Ultimately, our clients see results and a great ROI from these labeling solutions.”

Benefits of Long-Range Scanning

According to LeBlanc, long-range scanning offers warehouse operators three primary benefits:

- Improved barcode scan accuracy – Long-range scanning improves readability and productivity for stocking and picking.

- Increased warehouse capacity – When long-range scanning is implemented, warehouses are able to expand available space by using higher rack levels.

- Reduced picking errors – Ultimately, long-range scan labels help to drive operational efficiencies and speed by ensuring warehouse workers locate and pick inventory accurately and quickly.

Long-Range Scanning for Overhead Warehouse Signs

Overhead warehouse signs are highly recommended for identifying and managing bulk storage inventory. They typically contain a barcode image and human-readable numbers or letters.

Long-range mobile scanning technology is required for this set up. Signs with retro-reflective graphics ensure easy and accurate scans.

“Many of today’s scanners can read 1D or 2D barcode images up to 50 feet away or more,” LeBlanc said. “This means workers can quickly and safely scan bulk locations without leaving their lift trucks.”

Before installing overhead bulk storage signs, floors should be professionally striped for optimum efficiency and organization.

It takes experience, knowledge and specialized equipment to accurately and safely hang signs and stripe floors. ID Label’s experienced installation crews can help install signs so that they are properly located and angled to maximize scanning efficiency.

Many of today’s scanners can read 1D or 2D barcode images up to 50 feet away or more. This means workers can quickly and safely scan bulk locations without leaving their lift trucks.

Retroreflective rack labels can be installed to wrap around the bottom of the beam face to allow for an accurate scanning angle from ground level.

Long-Range Scanning for Warehouse Rack Labels

Warehouse rack labels mark each rack bay location and are used to identify products for storing, picking and inventory management.

Rack labels can be manufactured using retroreflective graphics for long-range scanning. This is desirable when person-down lift trucks are being used and there aren’t totem labels installed to identify upper rack levels.

In this case, labels on higher levels are typically wrapped around the bottom of the beam face to allow for an accurate scanning angle. This allows warehouse employees to scan upper level rack beams while stationed on the floor.

The retro-reflective material promotes optimal scan accuracy due to the intensity of the returned light to the scanner.

Operations without long-range scanning capabilities may employ color-coded totem labels at eye level. These labels contain multiple barcodes, each representing a rack level. Totem labels are typically paired with companion labels in matching colors placed at each corresponding bay level to help workers visually identify the correct level and location.

ID Label can create custom rack beam labels to meet your specific warehouse needs, and ensure consistent and accurate long-range scans.

ID Label’s retroreflective rack labels feature premium materials and construction to ensure durability and performance.

Ready to Implement Long-Range Retroreflective Labeling?

“Whether you’re in the process of planning a new warehouse or updating your current facility, we encourage our customers to call us to discuss your best options,” said LeBlanc. “As a custom manufacturer, we’ll design a solution for your specific environment and mobile technology. We even offer turnkey installation services.”

The ID Label Advantage

ID Label manufactures extremely durable warehouse rack and bin location labels. Our materials have been tested and used in warehouse operations around the globe.

We also provide warehouse signage and turnkey nationwide installation services to provide a complete solution to our many clients who rely on us for all their warehousing needs.

Interested in learning more? Contact us today.