Roadmap to a Successful Warehouse Label and Sign Installation Project

Whether you’re constructing a new warehouse or reconfiguring an existing facility, installing thousands of new barcode labels and signs can be a daunting task.

At ID Label, we know this better than anyone. We manufacture and professionally install millions of warehouse labels and signs every year.

We spoke to Brian Blair, ID Label’s manager of installation services, about how best to prepare for an installation project with us and put together a brief roadmap of the key phases involved.

“It’s important to verify that your facility is ready for label installation. That includes ensuring the racking aisles are free and clear of materials and construction equipment, and that the racks are clean and ready to be labeled.”

“It’s important to verify that your facility is ready for label installation. That includes ensuring the racking aisles are free and clear of materials and construction equipment, and that the racks are clean and ready to be labeled.”

– Brian Blair, ID Label

Phase I: Planning and Estimating

“Advance planning and preparation is key,” Blair said. “We recommend contacting us 8-12 weeks in advance of your desired completion date to get the ball rolling.”

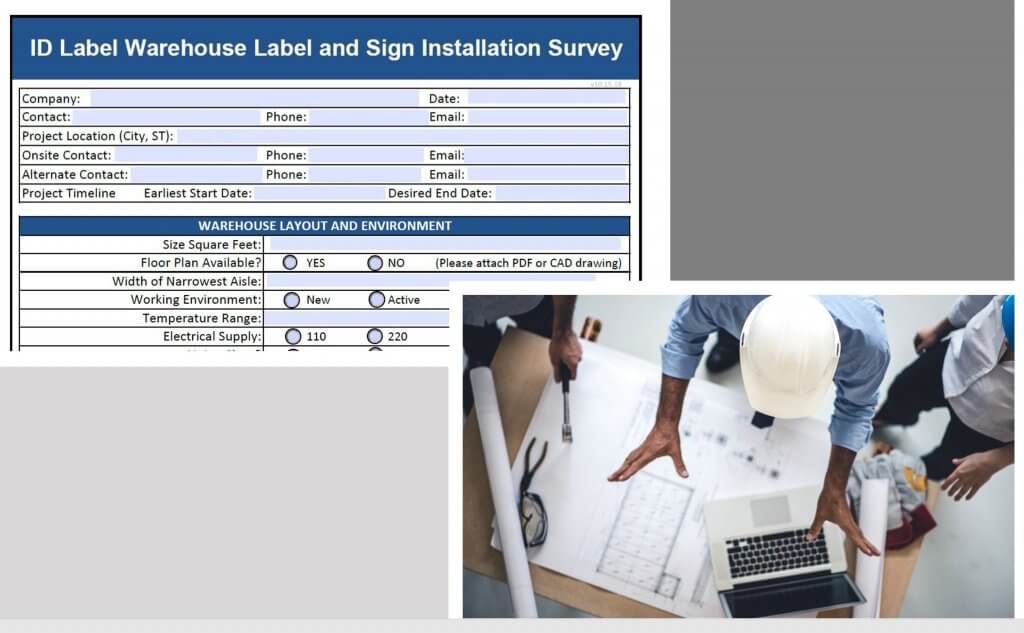

Clients begin by completing a survey to provide details on the warehouse floor plan and environment. This includes specific information on rack beam conditions, height, number of levels, label and sign quantities, sizes and more.

“This information allows us to recommend specific product types, an installation approach and an accurate project estimate,” Blair said.

Phase II: Design and Production

From there, once a PO has been cut and a deposit received, ID Label develops design proofs of the labels and signs for review and approval prior to production.

“During this phase, it’s critical that clients submit accurate, formatted data files that properly delineate characters for each aisle, bay and level,” Blair said, “as that’s what will be printed and manufactured.”

Learn more about data-file preparation here.

Allow 2-3 weeks for the production cycle, plus time for shipping the finished goods to your site.

Meanwhile, ID Label will confirm the installation date, assign a crew and make necessary equipment rental and travel arrangements.

Phase III: On-Site Installation

When the installation date arrives, it’s important to verify that your facility is ready for the ID Label crew.

“That includes ensuring the racking aisles are free and clear of materials and construction equipment, and that the racks are clean and ready to be labeled,” Blair said.

For every warehouse label and sign installation project, ID Label provides complete planning and project management services through every step of the process. Contact us to learn more.

Download: “Checklist for Your Next Warehouse Label Installation Project”

Download our free guide to learn more about preparing for your next warehouse or distribution center label installation project.

The ID Label Advantage

ID Label manufactures extremely durable warehouse rack and bin location labels. Our materials have been tested and used in warehouse operations around the globe.

We also provide warehouse signage and turnkey nationwide installation services to provide a complete solution to our many clients who rely on us for all their warehousing needs.

Interested in learning more? Contact us today.