Barcoding and Warehouse Management Systems Fuel Growth of Wearable Technology

Wearable technology has an increasingly growing presence in all aspects of our daily lives, so it is only logical that the next area for significant growth is in the workplace. These devices are helping warehouse operations leverage the power of warehouse management systems (WMS) as the technology becomes more commonplace within the industry.

Though nearly one in three warehouses are still not using WMS technology, one recent study forecast that the WMS market is expected to reach $4.82 billion by 2024, more than doubling the size ($2.06 billion) of the market in 2018.

“Warehouse management systems and wearable devices are ushering in a new era of workplace technology, and barcoding is at the center of this evolution,” said Neal Lulofs, ID Label’s chief marketing officer. “This new era will be defined by unprecedented workplace efficiency, with the supply chain industry among those with the most to gain.”

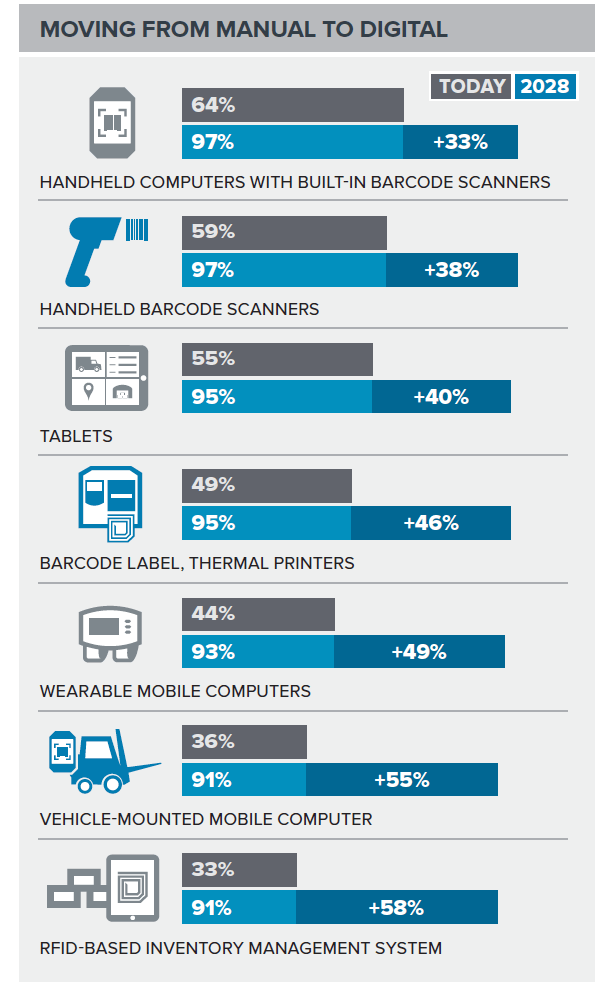

97% of supply chain operations will incorporate handheld barcode scanners by 2028, a 38% increase from today. By the same time, it is expected that more than 90% of supply-chain decision makers will invest in wearable technology.

97% of supply chain operations will incorporate handheld barcode scanners by 2028, a 38% increase from today. By the same time, it is expected that more than 90% of supply-chain decision makers will invest in wearable technology.

Warehouse Technology Transformation

According to a recent survey by Zebra Technologies, 97% of supply chain operations will incorporate handheld barcode scanners by 2028, a 38% increase from today. By the same time, it is expected that more than 90% of supply-chain decision makers will invest in wearable technology.

The shift to smarter warehouse labeling systems is already happening right in front of our eyes. As we look to the future of technology in the logistics and warehouse workplace, here are three key benefits already being realized from the use of wearable devices:

Go Hands Free

Keeping workers moving with hands-free scanning is key to optimizing the efficiency of warehouse barcode systems. Smart gloves help workers scan labels with barcodes up to two times faster than traditional handheld devices by eliminating the need to carry and reach for a bulky device on a tool belt. Volkswagen implements this technology at more than 40 locations across the globe, and has seen productivity improve by as much as four seconds per pick. For locations requiring millions of picks per year, the time and cost savings can be substantial.

Get a Head’s Up

Smart glasses may not have yet received widespread adoption among consumers, but they represent one of tech’s greatest areas of potential in the workplace. A study by Gartner predicts shipments of head-mounted display technology will grow by 45 million between 2019 and 2022.These glasses provide workers with a heads up display (HUD) that can provide valuable information within their natural field of vision. These devices can also leverage voice commands and even provide scanning capabilities for warehouse barcode labels.

DHL Supply Chain is among the first adopters of the technology, piloting a program to help employees select carts. By providing visual cues for picking and sorting functions, the glasses helped produce a 10% improvement in productivity compared to traditional handheld devices.

Give Better Feedback

Much like fitness trackers can tell joggers how far and how quickly they ran, wearable technology can help warehouse managers monitor the movements of workers. Amazon is one leader in the space that has already secured patents for armbands that will track employee movement. It is expected that the bands will track an employee’s location in relation to a target inventory item and provide sounds or even vibrating pulses to help select the right item from the warehouse rack. Additional tracking data could also potentially be used to review and increase the efficiency of routes employees take to a given item and track the time an employee spends between tasks.

ID Label has worked with thousands of organizations to deliver custom barcode label solutions that improve operational efficiencies.

“As part of our engineering design process, we ensure that our barcode symbology, label materials and graphics all work seamlessly with your WMS system for completely accurate scanning, whether workers are using wearables or handheld scanners,” Lulofs said.

As part of ID Label’s engineering design process, we ensure that our barcode symbology, label materials and graphics all work seamlessly with your WMS system for completely accurate scanning.

The ID Label Advantage

ID Label manufactures extremely durable warehouse rack and bin location labels. Our materials have been tested and used in warehouse operations around the globe.

We also provide warehouse signage and turnkey nationwide installation services to provide a complete solution to our many clients who rely on us for all their warehousing needs.

Interested in learning more? Contact us today.

Tags

Recent Posts

- The Essential Role Labeling Plays in Food Traceability

- Ask the Expert: Should I Choose Paint or Tape to Mark My Warehouse Floors?

- Scott Bender Joins ID Label as Vice President of Sales

- Structural vs. Roll Form Steel: Labeling Insights for Both Warehouse Racking Types

- Barcodes: The Foundation of New Data Capture Technologies