Distributor Gains Flexibility and Productivity with Clean Release™ Shelf Labels

ID Label Success Story

This ID Label customer is a national distributor of fitness, rehabilitation and health/wellness products, with multiple distribution centers across the U.S.

Julie Vanni, an ID Label business development manager, explains how a warehouse manager was able to improve productivity and operational efficiency with ID Label’s custom solution.

“The customer typically had to scrape off and replace more than 500 label sets each month. They were using paper labels with permanent adhesive, which weren’t durable. Worse than that is how difficult they were to remove and replace. “

– Julie Vanni, ID Label

Q: What challenge was your customer facing?

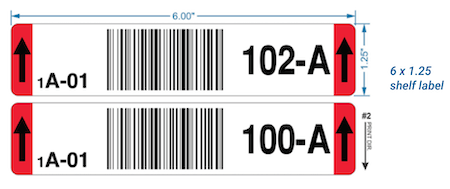

A: This distributor had thousands of items stored in barcoded shelf locations. Each location had two small side-by-side labels used to convey a description about the item, its part number and some other information. These labels need to be swapped out multiple times per year due to product changes and seasonal selling cycles.

The challenge our customer had is they were using cheap paper labels with permanent adhesive printed in-house. These kind of labels are not very durable, so they can be easily damaged. Worse than that is how difficult they are to remove and replace. Workers were wasting untold hours scraping off shelf labels, replacing them with new labels, and then repeating that process in a vicious circle. On average, more than 500 label sets had to be scraped off and replaced each month.

Q: How did the customer discover ID Label and its solutions?

A: We’ve worked with this customer for a very long time. Over the years they’ve relied on us for LPN labels, warehouse signs and floor location kits, among other products.

Q: What were the steps in the process that led to a recommended labeling solution?

A: When I heard about the challenges they were having with their paper shelf labels, I introduced them to our Clean Release™ repositionable labels. They feature an advanced adhesive that keeps them firmly in place for years, but they can be easily removed by hand without any scraping required and there’s no adhesive residue left

The process was fairly straightforward: we sent them some samples to test on their shelf locations. They immediately recognized the huge improvement in product quality and understood the tremendous time and productivity gains they would benefit from.

“The Clean Release labels have been a tremendous time saver for them. It gives them the flexibility to make location changes on the fly without time wasted scraping off old labels. Our main point of contact joked: ‘The Clean Release labels are really going to save my fingernails!'”

– Julie Vanni, ID Label

Q: Did you incorporate any unique engineering or design elements?

A: First, these are poly labels. So they’re much more durable than the paper shelf labels they had been using.

In addition, some of the Clean Release labels were produced with a yellow flood-coat background. They use these labels to catch worker attention at locations where special care is required due to the nature of the product and the picking process.

Q: What overall benefits did the customer achieve?

A: As I mentioned, the Clean Release labels have been a tremendous time saver for them. It gives them the flexibility to make location changes on the fly without time wasted scraping off old labels.

Our main point of contact joked: “The Clean Release labels are really going to save my fingernails!

They recently invested in some new person-down lifttrucks. We’re beginning to work with them on new totem-style labels—using Clean Release construction—for their warehouse racking to support their new picking/putaway process.

The ID Label Advantage

ID Label manufactures extremely durable warehouse rack and bin location labels. Our materials have been tested and used in warehouse operations around the globe.

We also provide warehouse signage and turnkey nationwide installation services to provide a complete solution to our many clients who rely on us for all their warehousing needs.

Interested in learning more? Contact us today.